PRODUCT CENTER

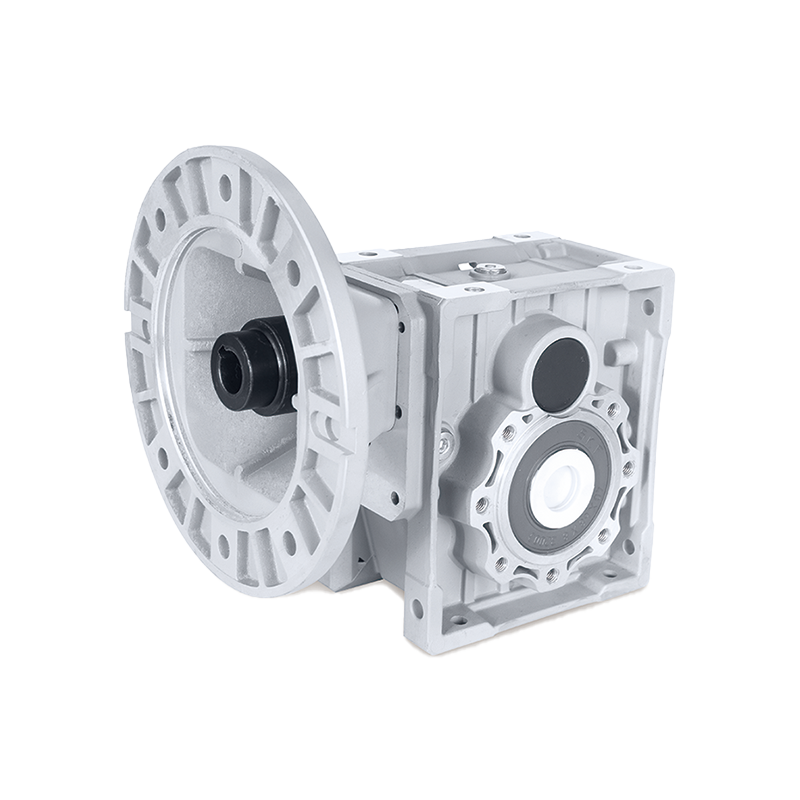

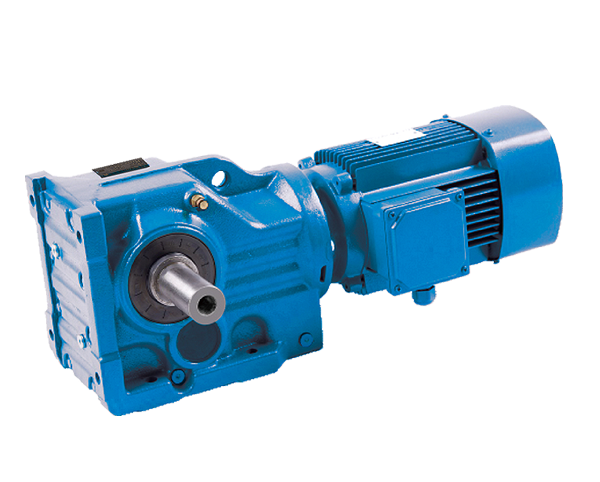

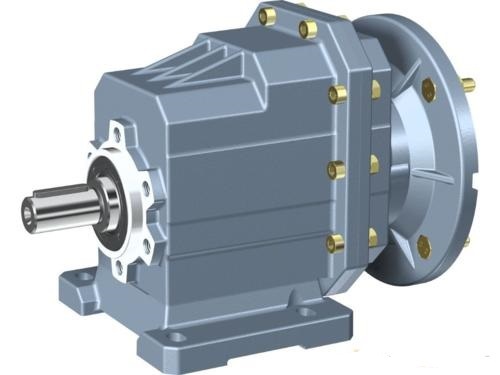

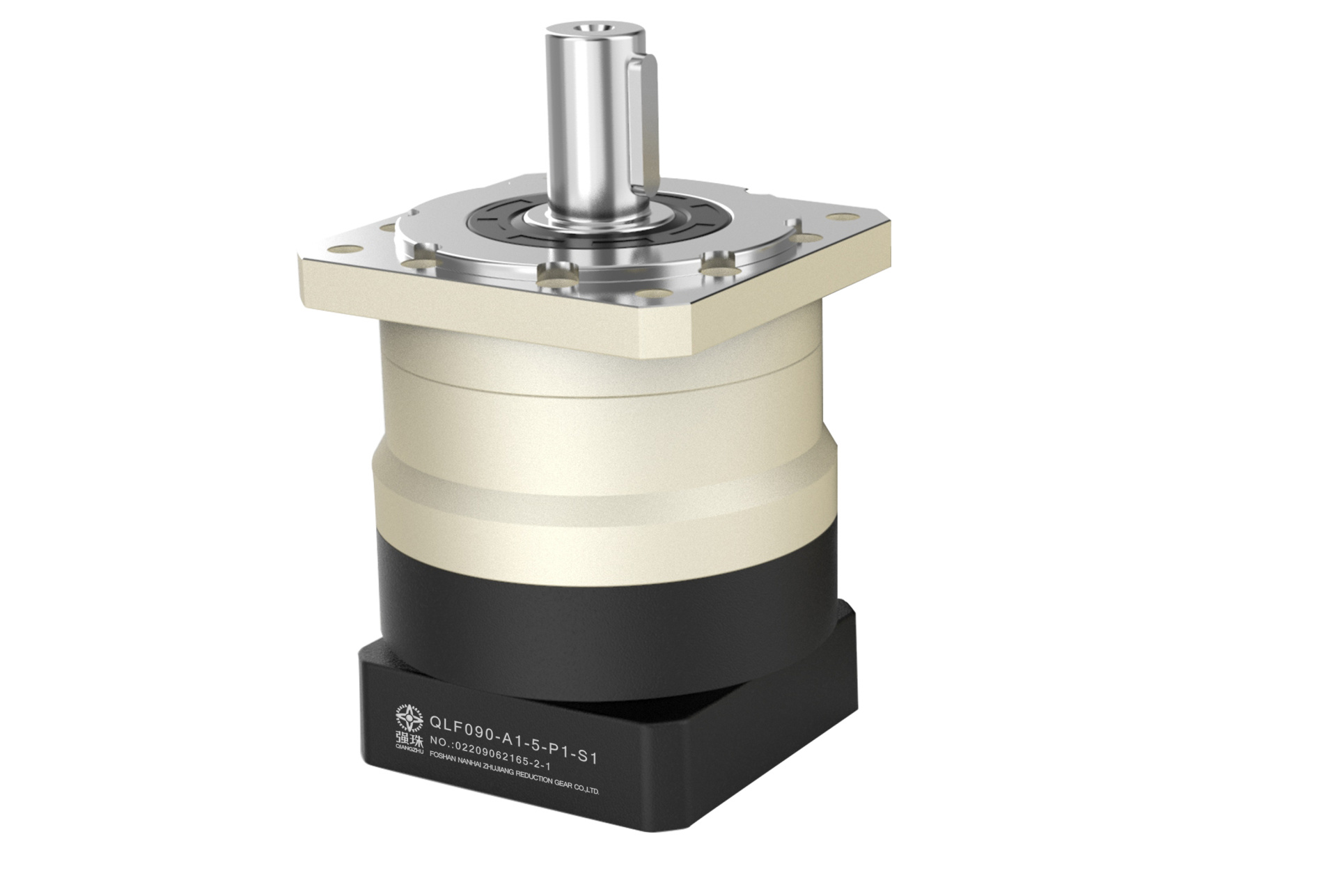

Gear reducer is suitable for mechanical tools to set different speeds and different processing requirements. Common types of gear reducers use pulley pairs of different diameters, gearboxes, and reinforced electric motors. The most common reducer includes: worm gear reducer, bevel gear reducer, spiral gear reducer, parallel shaft gear reducer, etc... welcome to inquire!

LATEST PRODUCTS

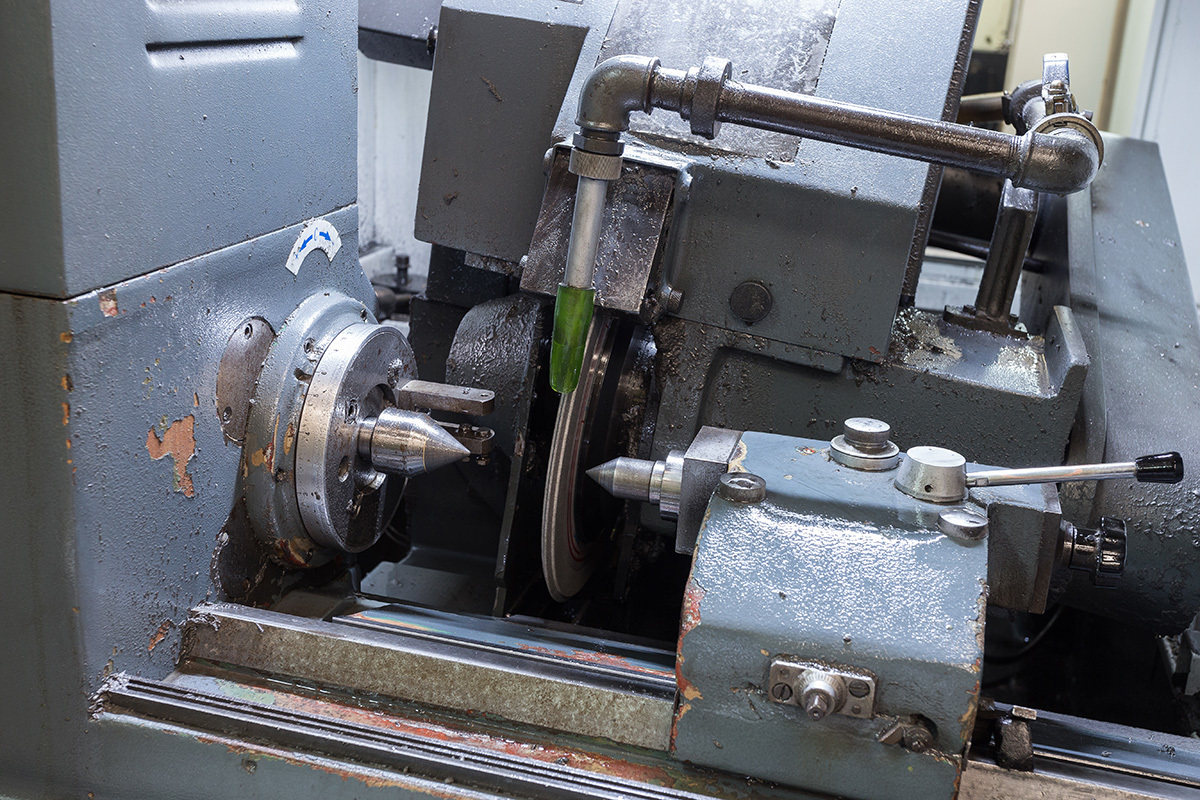

Mainly produces crankshafts, auto parts, agricultural machinery castings, construction machinery parts, mining machinery parts processing and sales

ABOUT US

Foshan Nanhai Zhujiang Reduction Gear Co.,Ltd

Foshan Nanhai Zhujiang Reduction Gear Co.,Ltd(the "Company") was established in 1992, located in Nanhai District, Foshan City, Guangdong Province,We have around 280 employees, technical engineers are up to 30, 10 of them are senior engineer.accounting land area of 50,000 square meters, construction area of 45,000 square meters, the company specializes in the production of various types of gearbox, we are one of the larger gearbox manufacturers in the South China.

The Factory Covers An Area of

Company Founded

Company Has Employees

CNC Equipments

NEW CENTER

Jun 28,2025

Innovative Solutions: Harnessing the Power of Worm Gear Reducers for Enhanced Mechanical Efficiency

Innovative Solutions: Harnessing the Power of Worm Gear Reducers Table of Contents 1. Introduction to Worm Gear Reducers 2. The Mechanics of Worm Gear Reducers 3. Advantages of Using Worm Gear Reducers 3.1 Enhanced Torque Output 3.2 Compact Design and Space Efficiency 3.3 Quiet Operation and Vibration Reduction 4. Applications of Worm Gear Reducers in Various Industries 4.1 Manufacturing and Autom

Jun 27,2025

Understanding Worm Gear Reducers: The Key to Efficient Motion Control

Worm gear reducers, a crucial component in the automotive and mechanical transmission industry, play a significant role in enhancing the efficiency of motion control systems. These specialized gear systems consist of a worm (a screw-like component) and a worm gear (a toothed wheel) that work together to reduce speed while increasing torque. Understanding the mechanics and applications of worm gear

Jun 26,2025

Enhancing Performance: The Impact of Worm Gear Reducers on Vehicle Dynamics

Enhancing Performance: The Impact of Worm Gear Reducers on Vehicle Dynamics Table of Contents 1. Introduction to Worm Gear Reducers 2. Understanding Vehicle Dynamics 3. The Mechanics of Worm Gear Reducers 3.1 What is a Worm Gear Reducer? 3.2 Key Components of Worm Gear Reducers 4. Benefits of Using Worm Gear Reducers in Vehicles 4.1 Improved Torque and Power Transmission 4.2 Enhanced Energy Effici

GLOBAL SERVICE

30 years of top-down Pearl who always care management reducer production and sales, the relentless pursuit of brand products, with performance improving the image of the concept of gear, the products have been sold to various regions and cities across the country, the majority of users.

OFFICIAL WEBSITE

Copyright © 2023 FOSHAN NANHAI ZHUJIANG REDUCTION GEAR CO.,LTD