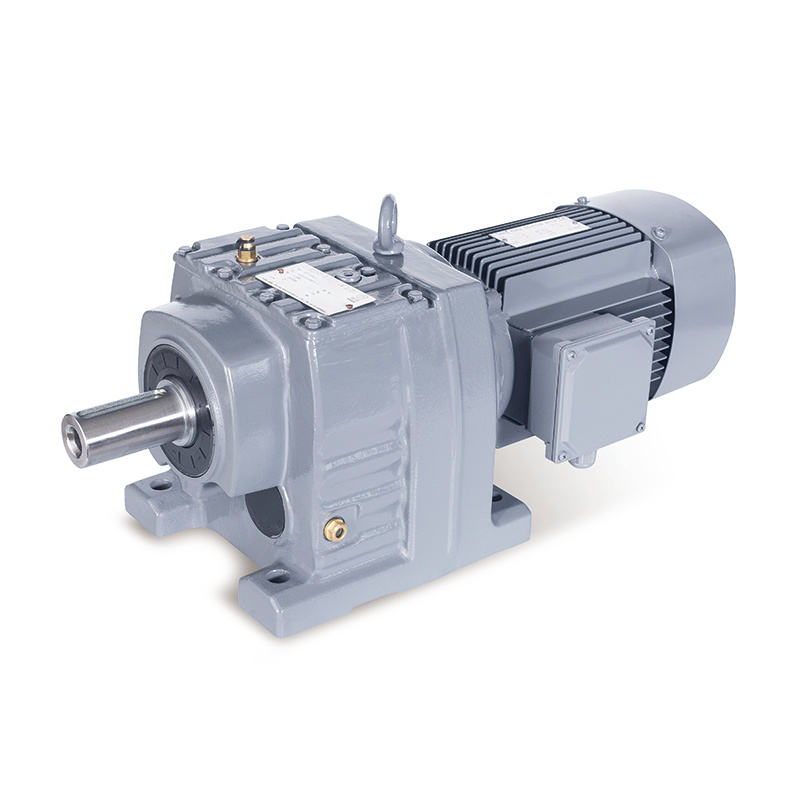

Helical speed reducer

Release time:

Feb 20,2025

1. Structure and Principle

Helical Gear Design

The key to the helical speed reducer lies in its helical gear components. The tooth surface of the helical gear is helical. Compared with other types of gears, it gradually enters and disengages from the meshing state when meshing. This feature makes the transmission between gears smoother and reduces the impact force caused by sudden contact and separation.

Internal Structure

The internal structure is compact and reasonable, usually consisting of an input shaft, a helical gear set, an output shaft, and necessary support and sealing components. The input shaft transmits power to the helical gear set, and after deceleration, the output shaft outputs the appropriate speed and torque.

2. Performance Characteristics

High Efficiency and Energy Saving

Due to the good meshing performance of the helical gear, the helical speed reducer has a high transmission efficiency. During operation, it can effectively reduce energy loss and convert more input energy into useful output, thereby achieving energy saving. This can significantly reduce energy costs in long-term industrial equipment.

Large Torque Output

A larger torque output can be achieved according to different design requirements. Whether in heavy-loaded mining machinery, large-scale construction equipment or various transmission devices in industrial production, helical speed reducers can provide sufficient torque to drive the equipment to operate normally.

Low-noise operation

The progressive meshing of helical gears makes the noise generated during the transmission process extremely small. This feature makes the helical speed reducer perform well in environments with high noise control requirements, such as indoor workshops, equipment near office areas and other application scenarios.

3. Application Scope

Industrial Production

In various industrial production lines, such as food processing, chemical raw material production, plastic product manufacturing, etc., helical speed reducers are used for power transmission of equipment such as conveyors, mixers, extruders, etc. to ensure stable and efficient operation of equipment.

Material Handling

In cargo handling equipment in the warehousing and logistics industry, such as automatic shelves and material hoists, helical speed reducers provide equipment with appropriate power and speed to ensure smooth material handling.

Machinery Manufacturing

In machine tools, milling machines and other equipment in machinery manufacturing enterprises, helical speed reducers help control the speed and torque of equipment and improve processing accuracy and efficiency.

OFFICIAL WEBSITE

Copyright © 2023 FOSHAN NANHAI ZHUJIANG REDUCTION GEAR CO.,LTD