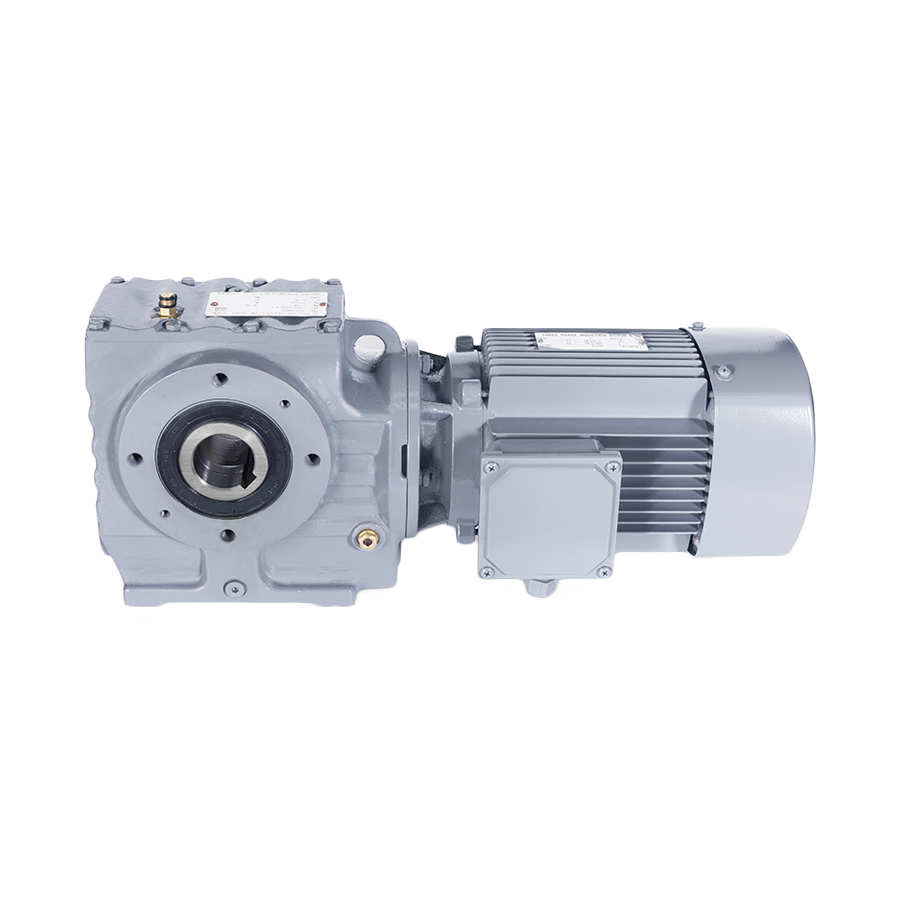

Parallel shaft gear reducer

Release time:

Feb 20,2025

1. Structural principle

Parallel shaft structure

The core structural feature of the parallel shaft gear reducer is that it has parallel input and output shafts. This parallel shaft design makes the power transmission direction more direct and smooth. Inside the reducer, the reduction function is achieved through a series of meshing gears. These gears are usually installed on parallel shafts and combined according to different gear ratios to achieve the purpose of reducing speed and increasing torque.

Gear system

Gears are the key components of parallel shaft gear reducers. They are generally made of high-quality metal materials, such as high-strength alloy steel. The machining accuracy of the gears is very high, and the tooth surface is finely ground to ensure good meshing performance. Different types of gears, such as cylindrical gears, can be selected according to specific application requirements. Compared with spur gears, helical cylindrical gears have the advantages of smoother meshing and stronger load-bearing capacity.

2. Performance advantages

Efficient transmission

Due to its precise gear design and manufacturing process, the parallel shaft gear reducer can achieve efficient power transmission. Under normal working conditions, the transmission efficiency can reach a high level, reducing energy loss, thereby saving energy costs for users.

High torque output

With reasonable gear ratio configuration, it can convert the input high-speed and low-torque power into low-speed and high-torque output. This high-torque output capability makes it suitable for various equipment that requires large torque drive, such as conveyor belts, hoists and other industrial equipment.

Strong reliability

High-quality gears and sturdy housing structure make the parallel shaft gear reducer very reliable. It can operate stably for a long time in harsh industrial environments, withstand large load pressure, and has good wear and fatigue resistance.

3. Application range

Manufacturing

In the machinery manufacturing, automobile manufacturing and other industries, parallel shaft gear reducer is widely used in various production equipment, such as the spindle drive of machine tools, the conveying equipment of automobile production lines, etc.

Logistics and warehousing

In the automatic sorting system of logistics warehouses, cargo lifting equipment, etc., it provides stable power reduction transmission for equipment to ensure the efficient operation of logistics.

Construction engineering

Parallel shaft gear reducer also plays an indispensable role in tower cranes, concrete mixers and other equipment at construction sites.

OFFICIAL WEBSITE

Copyright © 2023 FOSHAN NANHAI ZHUJIANG REDUCTION GEAR CO.,LTD