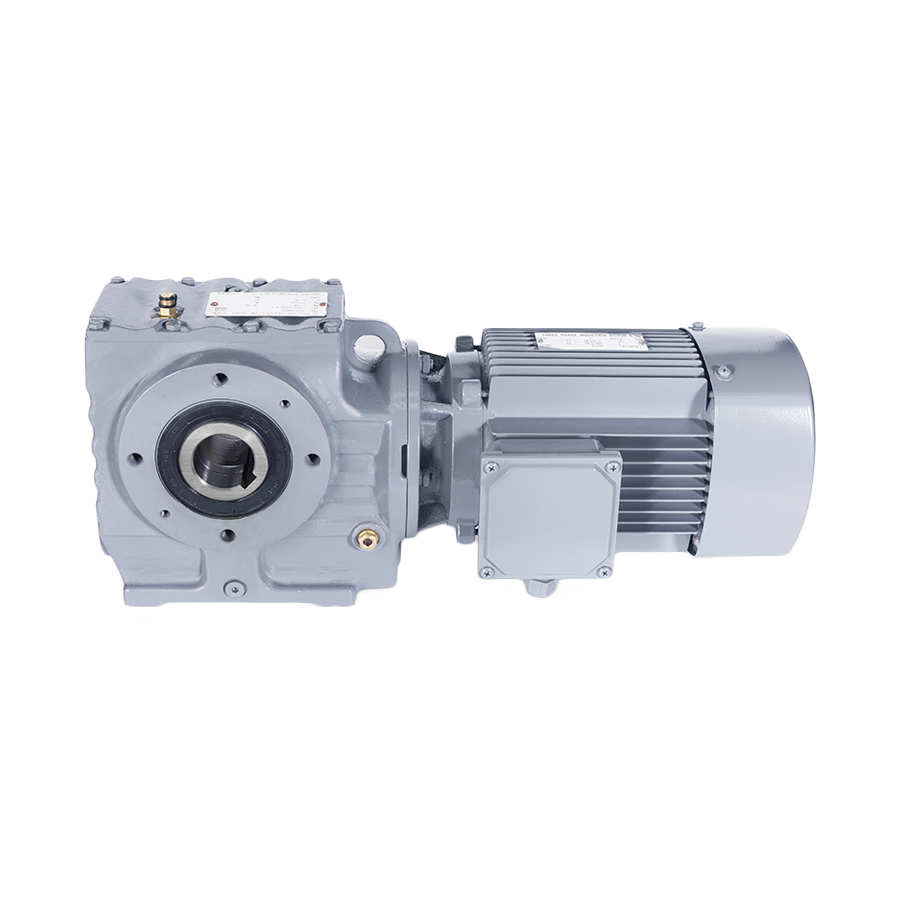

S series helical worm gear motor

Classification:

K/S/R/F series

Key words:

cathode material

PRODUCT DESCRIPTION

Product name: S series helical worm gear motor

"S series helical worm gear motor" is a high-performance industrial transmission equipment widely used in various mechanical systems. This product uses advanced design and manufacturing technology and has the following characteristics:

High efficiency and energy saving: S series helical worm gear motor is made of high-quality materials and has the characteristics of high efficiency and low energy consumption, which can effectively reduce energy consumption and save production costs.

Powerful transmission force: This reduction motor has a compact structure and large output torque. It can transmit power stably and efficiently and is suitable for work under various load conditions.

Ultra-quiet design: S series helical worm gear motor adopts advanced shock-absorbing design and high-quality bearings, with stable operation and low noise, and is suitable for occasions requiring low-noise environments.

Reliable and durable structure: This product is made of high-quality materials, with a sturdy and durable shell structure, reasonable overall design, long service life, and easy maintenance.

A variety of specifications are available: S series helical worm gear motor is available in a variety of specifications and models to meet different engineering needs and can be widely used in various industrial fields.

Product parameters:

Product specification: 37-97

Transmission ratio: 6.8-33818

Input power: 0.12-22KW

Output torque: 11-4000Nm

GET FREE PRODUCT QUOTES

OFFICIAL WEBSITE

Copyright © 2023 FOSHAN NANHAI ZHUJIANG REDUCTION GEAR CO.,LTD